A TWO CENTURY TRADITION, BUILT ON STEEL

Who We Are

With locations in South Portland, ME, West Bath, ME, Auburn, MA, Syracuse, NY and Fremont, NH, American Steel and Aluminum (ASA) efficiently delivers top-quality steel and metal solutions for customers across a host of industries – ranging in size from large U.S. government contractors to local fabricators.

We are proud to partner with a diverse customer base; providing support to business sectors that include U.S. Navy shipbuilding, industrial equipment manufacturing, robotics, large scale stadium seating, structural steel fabrication, and precision sheet metal manufacturing.

Why Choose American Steel and Aluminum

Precision Material Processing

Industry-leading cut quality and processes for high-precision and accuracy every time.

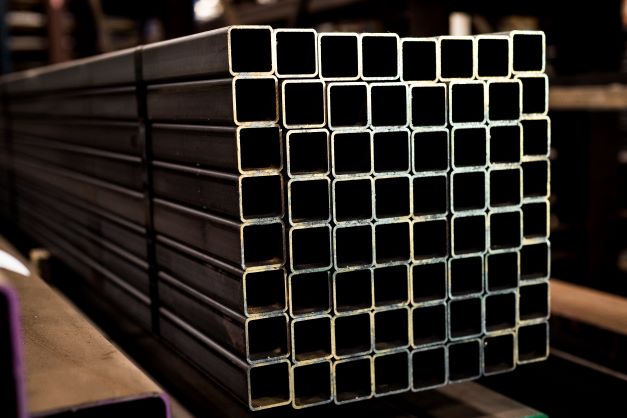

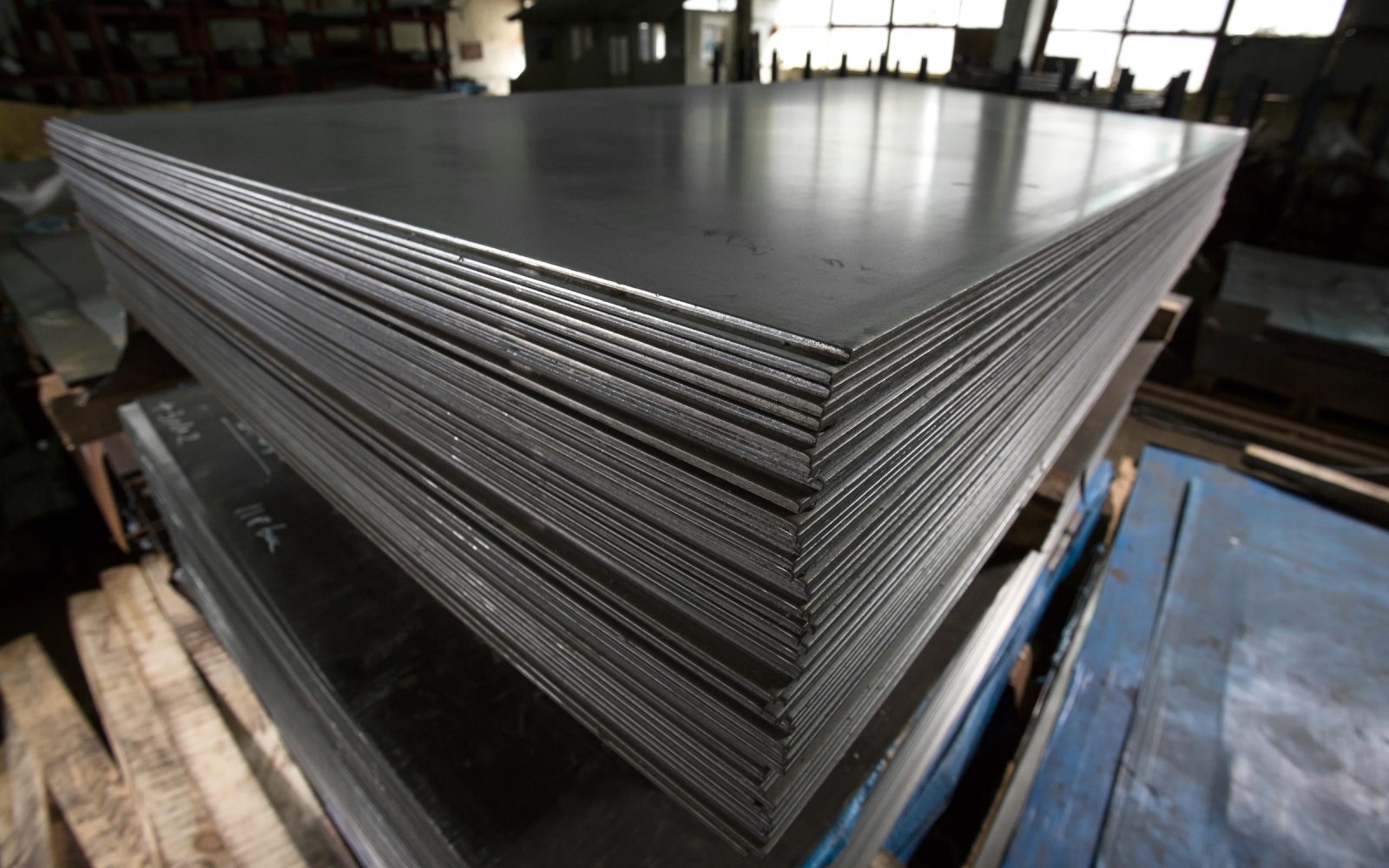

Deep inventory of products

Extensive on-site inventories mean we can respond quickly to fulfil large, small and custom orders for a wide range of products.

World Class Commitment to Quality

Our experts work with customers to deliver high-quality parts and components using the latest laser, plasma , and oxy cutting technology.

Inventory management and value add services

We view ourselves as an extension of our customers operations. Our inventory management, kitting and just-in-time delivery services are designed to improve manufacturing processes.

What We Offer

Custom solutions for your sheet, plate , tube and bar requirements. Our highly skilled Processing Team will work to understand your application and determine the best method to efficiently process your parts. Additional services, such as grinding, deburring, bending, machining, and kitting are also offered. With 5 locations, the latest processing equipment, and our own fleet of trucks, we can respond and get your parts produced and delivered quickly.

Product line

10+ Products

Metals

4 Types

Processing capabilities

15+ Capabilities

ALUMINUM

STEEL

COATED

Our Mission

As a leader within the metals industry, American Steel and Aluminum (ASA) strives to be a world-class strategic partner to our customers and suppliers. By continuously investing in new emerging and innovative technologies, talent, and modernized best practices – ASA can ensure we continue to deliver industry leading customer service and consistent quality products.

About AMERICAN STEEL & ALUMINUM

With locations in West Bath, ME, South Portland, ME, Auburn, MA, Syracuse, NY and Fremont, NH, American Steel and Aluminum (ASA) efficiently delivers top-quality steel and metal solutions for customers across a host of industries – customers ranging in size from large U.S. government contractors to local fabricators.

Some of the many Sectors we support include the U.S. Navy Shipbuilding, industrial equipment manufacturing, stadium seating, structural steel fabrication, and precision sheet metal manufacturers.

Certificates and Partners

Get in touch

Feel free to reach out to us by phone, email or by submitting your message via the contact form.

Contact Information

Monday to Friday / 10am - 8pm